More than just drying – spray-drying as a way towards multifunctional materials

Spray-drying is a method that has gained in importance and recognition especially due to its use as a drying tool in engineering or in multiple processes in pharmaceutical and food industry. This procedure is based on the encapsulation of various components in the confined space of a liquid droplet before the latter is evaporated in a hot chamber so that its constituents are “forced” together. While spray-drying already demonstrates notable advantages in known processes due to its fast, easy, and scalable character, it still holds a far bigger potential that can particularly be developed in the world of material chemistry.

A comprehensive overview of this potential is given by a perspective article that has recently been published in the renowned journal Advanced Materials.

In this article, Karl Mandel (Professorship for Inorganic Chemistry) presents the possibilities and challenges of spray-drying as a method for the design of multifunctional materials together with experts in the field of spray-drying from all over the world – including Takashi Ogi, Daniel Maspoch, Andres Bück, Damien P. Debecker, und Marco Faustini.

This article shows the importance of spray-drying as a tool for the development of hybrid materials as this process enables unusual and unique combinations of components. In this way, it is demonstrated that applications of spray-drying go far beyond conventional drying procedures in industry and permit its use in diverse and novel fields, going from catalysis over diagnosis and purification to storage and information.

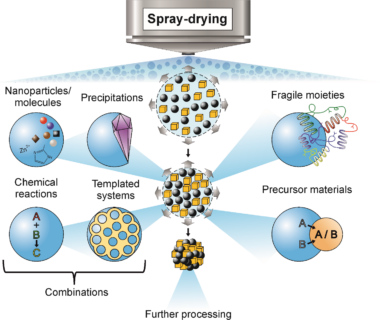

For example, spray-drying not only allows the combination of various nanoparticle components to a larger entity but also the implementation of precipitation reactions and chemical syntheses. Furthermore, it enables the design of templates, the processing of fragile moieties, and the production of precursor materials for further synthesis steps. All these products of the spray-drying procedure can then be further processed in multiple ways and thus pave the way for the next hierarchy level towards multifunctional materials.

The perspective article underlines the importance of spray-drying as a valuable tool for materials chemists to overcome the still existing challenges by research advances. In this way, this method could be used in fields in which it is still underused. Therefore, the goal is to produce more high-functioning materials for various and wide-ranging applications by spray-drying in the near future.

Further information

Publication: „Multifunctional, hybrid materials design via spray-drying: much more than just drying”, https://onlinelibrary.wiley.com/doi/10.1002/adma.202306648

Contact

Prof. Dr. Karl Mandel

Professur für Anorganische Chemie

karl.mandel@fau.de