Programmable Thermal Switches: Controllable Induction Heating in Nanoparticles at the Push of a Button

FAU researchers develop a switching principle for pinpoint heat generation – with potential applications in recycling, smart materials, and medicine

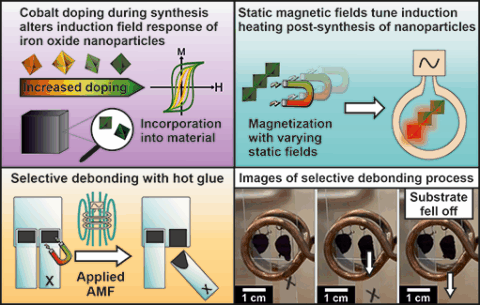

Whether in self-healing materials, targeted recycling processes, or even the cancer therapies of tomorrow – induction heating, the warming of magnetic materials through alternating magnetic fields, opens up countless possibilities. Until now, however, it was not possible to precisely control which particles heat up when and where. Researchers at FAU, in collaboration with key contributors from MIT and Forschungszentrum Jülich, have now achieved a major breakthrough: they have succeeded in “programming” magnetic nanoparticles to release heat on demand.

A single impulse – a lasting effect

The core of the study involves iron oxide nanoparticles that were selectively doped with cobalt. The key innovation: by exposing them once to a static magnetic field, their magnetic structure can be permanently altered – making them particularly efficient heat carriers when subjected to an alternating magnetic field. “The principle works like a switch that is flipped once – the effect then remains,” explains lead author Leoni Luthardt from the Chair of Particle-Based Materials Chemistry.

Heat where it’s needed

This “magnetic imprinting” has far-reaching consequences: not only can nanoparticles be locally activated – they can also be selectively embedded into materials, such as adhesives or polymers. In model experiments, the researchers showed that adhesive bonds can be selectively dissolved using this method – simply by magnetizing specific regions in advance and then applying induction heating. In the future, components could be more easily disassembled at the end of their life cycle or selectively repaired.

Towards thermal coding

“We’re talking about a thermal programming mechanism,” says project leader Prof. Dr. Karl Mandel. The magnetic properties – particularly the so-called coercive field strength – can be finely tuned via the cobalt doping. This not only makes it possible to control the heating power but also the activation threshold for the alternating field. With increasing cobalt content, a particle requires a stronger magnetization to be activated. This enables graded heating behaviors and complex thermal patterns to be achieved.

Outlook for smart recycling and programmable release

The potential applications are diverse: one possibility is targeted “debonding,” or detaching two materials on demand, to create smart adhesives. The approach could also be used for controlled release of different (active) substances from a particle reservoir. “Our particles are fundamentally compatible with a wide range of matrix environments. The underlying concept can thus also be applied to resource-efficient recycling processes or medical applications,” says Theodor Raczka, also lead author of the publication.

This research was supported by the funds AdRecBat (BMBF, No. 03XP0518C), SmartRust (ERC Consolidator Grant No. 101123921), and SFB 1411 (Project-ID – 416229255). Leoni Luthardt is furthermore funded by the German Federal Environmental Foundation (DBU).

The article was recently published in the journal Advanced Materials and can be accessed at: http://doi.org/10.1002/adma.202507158

Further information: